fact of the matter is

The fashion industry is one of the most destructive industries to our people + the planet:

that’s more than all maritime shipping & international flights combined

as of 2020

and there are over 300 million people globally working in the fashion industry

meanwhile, there are ~750 million people globally without access to clean drinking water

Another world

is possible

We certainly don’t have all the answers, but we’re putting our imaginations to the test & actively building the world we want to see. Here are the ways in which Blue Tin Production is not only meeting global standards in labor & sustainability, but calling them into question and setting new ones on how things can and should be.

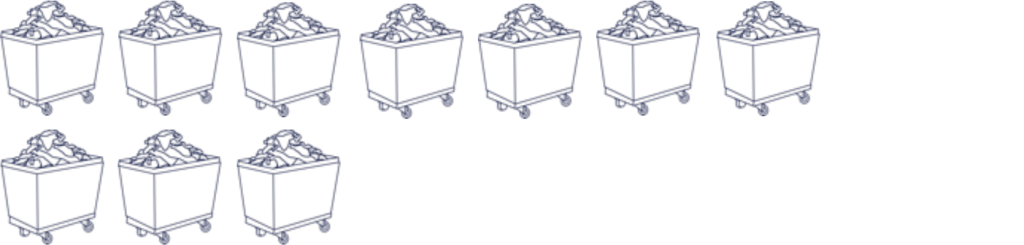

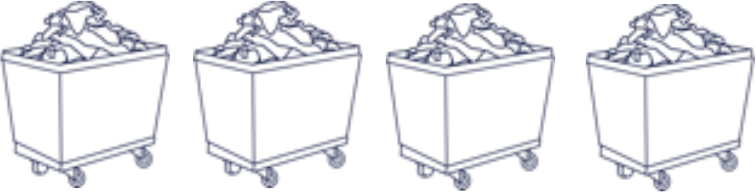

Fabric Waste Management

While many brands engage in greenwashing tactics by talking about their recycling programs, this does not include waste produced from manufacturing nor can most textiles actually be recycled.

Plastic Consumption in Production Facilities

Industry Standard

Blue Tin Production

zero plastic purchased + prioritizing designers that use natural and sustainable fabrics

Typical annual wages (USD) in Fast Fashion

*Wage theft is a common practice in the industry, with many factories around the world producing for major brands and household names owing millions (USD) in unpaid (or stolen/looted) wages

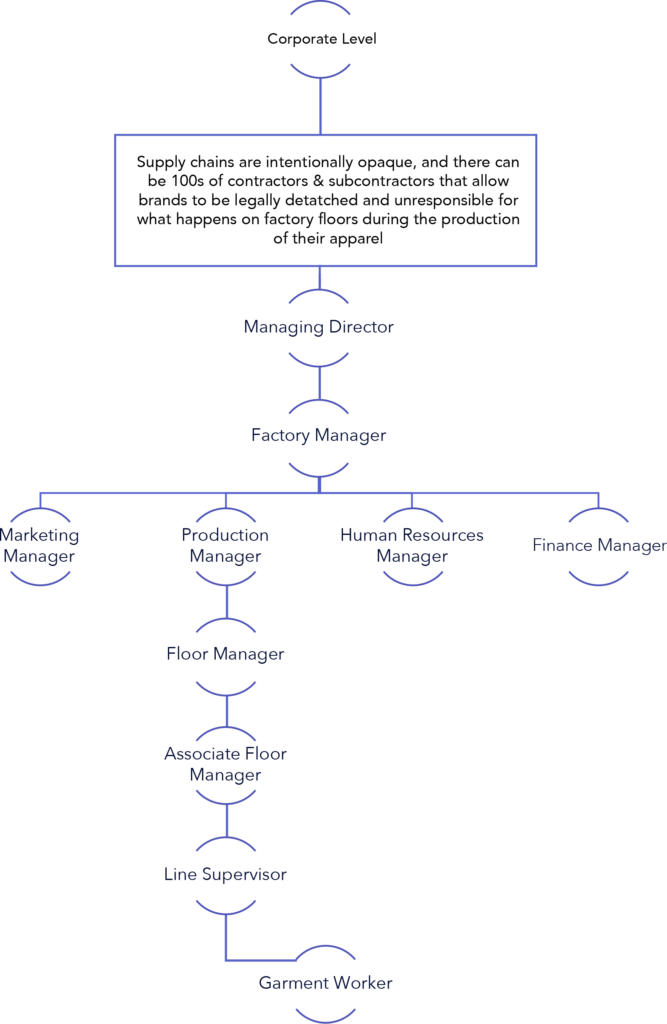

Worker co-operative: distribution of power & ownership

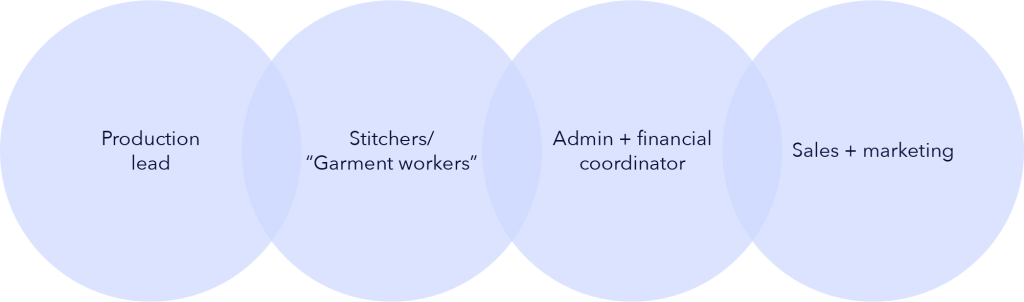

As a worker-owned and -run co-operative, all of the “members” of the co-operative collectively run the daily operations as well as other tasks necessary for production

The production lead for each project rotates among the members based on their specialized skill sets most relevant to the production at hand.

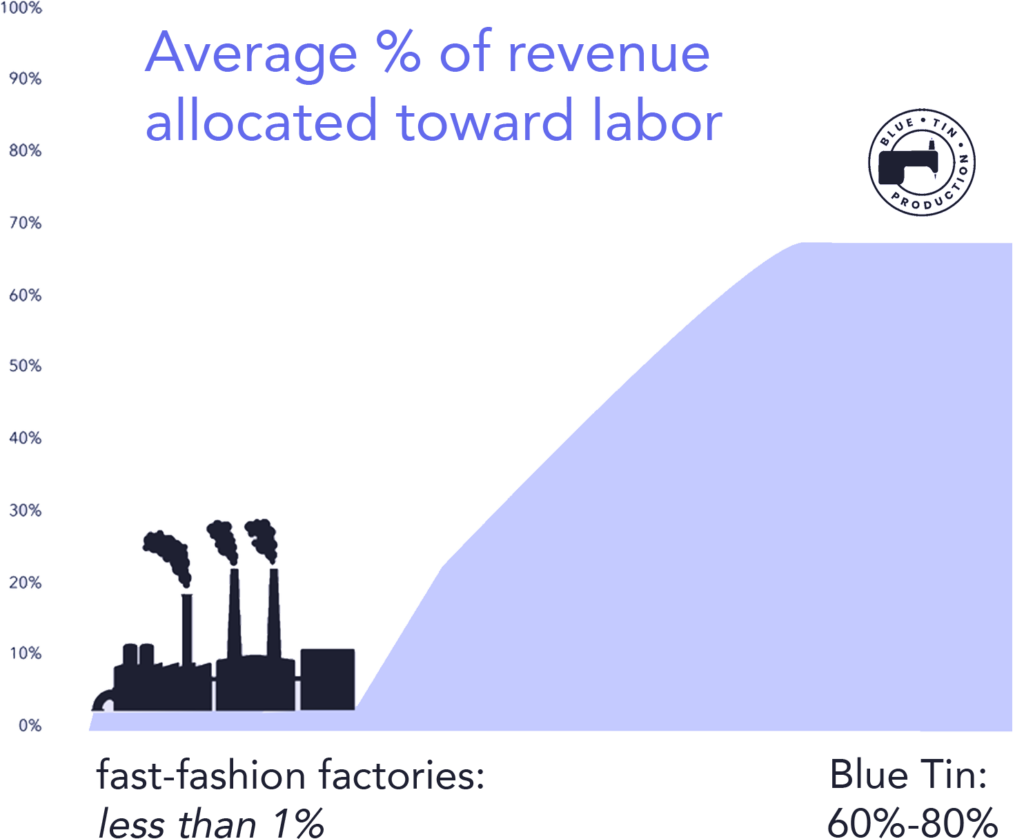

Profits are shared & distributed equally among the members every quarter. All of the members (minus one) are stitchers.

We don’t work with subcontractors, and require brands connect with our team directly in order to manufacture with us, challenging industry norms of long and opaque supply chains.

All decisions—including what designers are accepted, how waste is managed, salaries, hours, events, etc—are decided collectively

Everyone from members to interns and translators are, have been, and will continue to be, women of color, trans, gender non-conforming, intergenerational, queer, working-class, and/or immigrants and refugees.

A holistic approach to labor

Along with a collectively-set salary, members receive healthcare, mental health, access to social services, paid professional development, on-site interpreters and childcare as needed, educational and wellness trainings, and a workspace that is rooted in community and collective care above all.

In fast-fashion factories, garment workers are typically paid per piece or hourly, with overtime regular, mandatory, and unpaid.

Further Reading

Minh-Ha T. Pham | Jstor

A Series of Publications